Types of wood

I only use carefully chosen domestic hardwood and precious timbers (oak, holm oak, cherry tree, copper beech, ash, elm, sweet chestnut, olive, maple and other precious and suitable types) for building my didges. In doing so only the heart wood is processed, so this means no saw wood (industrial goods) is used.

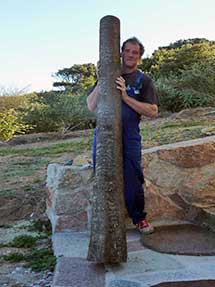

Furthermore, I only use one piece of the tree, namely the foot, because this has the highest quality of wood from the whole tree regarding, hardness, toughness and density. The trunks that are used for making my instruments have a diameter of approx. 18 – 30 cm. The process of building the instrument involves working out the hard core and removing the surrounding wood which tends to be of a lesser quality.

These woods are just as suitable for didgeridoos and often even better suited than eucalyptus wood. Eucalyptus is a very fast growing wood with a very high water content, which only partly becomes very hard after drying out. It is not seldom that the drying process results in the formation of cracks through the intensive shrinking.

When working with these types of wood I place great value on retaining the natural shape and the fibre course.